Environmental Benefits of Professional AC Repair in Greater Philadelphia: Reducing Energy Consumption and Carbon Footprint

Air conditioning systems represent one of the most significant contributors to energy consumption and carbon emissions across the Greater Philadelphia region, with particularly dramatic impacts during summer peak demand periods. Regional data from PECO reveals that cooling accounts for approximately 18-23% of annual residential electricity usage and up to 40% during summer months—figures that continue rising as climate change drives increasingly frequent and severe heat waves. During extreme heat events, air conditioning creates enormous demand spikes that strain the regional grid, with recent summer peaks reaching 8,200 MW—nearly double the baseline demand. This concentrated consumption drives both substantial carbon emissions and infrastructure challenges requiring costly grid enhancements. The Philadelphia metro area’s 1.2+ million residential cooling systems collectively consume approximately 2.1 billion kilowatt-hours annually, generating roughly 1.3 million metric tons of carbon dioxide equivalent—comparable to emissions from 280,000 passenger vehicles. These figures underscore the environmental significance of how efficiently these systems operate, with even modest efficiency improvements delivering substantial ecological benefits when multiplied across millions of cooling units.

Inefficient air conditioning systems create cascading environmental consequences extending far beyond simple energy waste. Each kilowatt-hour of unnecessary consumption generated by poorly maintained systems produces approximately 0.92 pounds of CO₂ emissions based on the regional electricity generation mix, contributing directly to climate change. These systems simultaneously exacerbate urban heat island effects through mechanical heat rejection that can raise localized ambient temperatures by 1-2°F in densely developed areas—creating a feedback loop that further increases cooling demand and energy consumption. Perhaps most significantly, neglected systems frequently develop refrigerant leaks that release hydrofluorocarbons (HFCs) with global warming potentials thousands of times more potent than carbon dioxide. A typical residential system contains refrigerant with greenhouse impact equivalent to 2-4 metric tons of CO₂ if released—making leak prevention a critical environmental priority. The collective impact creates an environmental burden disproportionately affecting vulnerable communities where older, less efficient systems predominate and where urban heat island effects are most pronounced, adding environmental justice concerns to broader ecological impacts.

Professional air conditioning repair and maintenance offer remarkable opportunities for environmental improvement through relatively modest interventions. Engineering analyses demonstrate that properly maintained systems typically consume 25-40% less energy than neglected equipment while delivering identical cooling output—creating substantial emissions reduction potential through cost-effective service rather than expensive equipment replacement. The environmental returns prove even more compelling when considering that approximately 65% of residential cooling systems in the Greater Philadelphia region currently operate below manufacturer efficiency specifications due to maintenance deficiencies. Systematic professional maintenance could potentially eliminate 330,000-520,000 metric tons of annual carbon emissions across the region—equivalent to removing 70,000-112,000 cars from the road. These improvements require no technological breakthroughs or significant consumer lifestyle changes, only the proper application of established maintenance protocols that simultaneously improve comfort, reduce costs, and extend equipment lifespan while delivering meaningful environmental benefits. Few environmental interventions offer comparable impact relative to the modest investments required.

Region Home Services has emerged as a Philadelphia-area leader in environmentally responsible AC repair since establishing their operations in 1974. Based in Bensalem and serving clients throughout Pennsylvania and New Jersey, they’ve developed specialized expertise in identifying and correcting efficiency losses that drive unnecessary energy consumption and environmental impact. Their technical approach emphasizes comprehensive system evaluation rather than simple component repair—addressing the interdependent factors that collectively determine operational efficiency. This methodology typically identifies 15-20% more efficiency opportunities than standard service approaches that focus solely on obvious deficiencies rather than optimizing complete system performance. Their technicians’ environmental expertise extends beyond mechanical repair to include proper refrigerant management—preventing the high-GWP refrigerant leakage that represents one of cooling systems’ most significant environmental impacts. This specialized knowledge has positioned Region Home Services as a particularly valuable resource for environmentally conscious property owners seeking to minimize their cooling systems’ ecological footprint while maintaining comfortable indoor environments through Philadelphia’s increasingly warm summers.

The company’s approach to air conditioning repair distinctively prioritizes both environmental protection and customer education through a unique service model. Rather than treating service calls as mere mechanical transactions, Region Home Services technicians function as system educators who help customers understand the environmental impact of their cooling choices. This consultative approach includes explaining efficiency metrics, demonstrating the emissions reduction potential of specific repairs, and providing practical guidance for optimizing environmental performance between service visits. Their “no shortcuts” philosophy ensures that environmental considerations remain central throughout the repair process, from refrigerant handling practices exceeding EPA requirements to comprehensive airflow optimization that maximizes efficiency. This environmental commitment extends to their ongoing customer relationships, with maintenance programs specifically designed to maintain peak environmental performance rather than merely preventing breakdowns. By transforming standard repair services into opportunities for environmental education and improvement, Region Home Services has established a service model that delivers meaningful ecological benefits while meeting customers’ practical cooling needs—demonstrating that environmental responsibility and business success can operate as complementary rather than competing objectives.

Energy Consumption Reduction Through Professional AC Repair

Professional air conditioning repair delivers quantifiable energy savings that vary significantly based on system condition, with particularly dramatic improvements possible in Greater Philadelphia’s challenging climate conditions. Comparative analysis of properly maintained versus neglected cooling systems reveals consumption differences of 25-40% under identical operating conditions, with the most substantial variances occurring during high-humidity periods that characterize Philadelphia summers. Engineering studies conducted throughout the mid-Atlantic region demonstrate that even systems appearing to function normally often operate far below their efficiency potential due to accumulated minor issues—with average performance degradation of 4-6% annually without professional intervention. These efficiency losses translate directly into increased energy consumption and environmental impact. For a typical 3-ton residential central air system, proper professional repair and maintenance reduces annual electricity consumption by 800-1,200 kWh compared to neglected equipment—eliminating approximately 735-1,100 pounds of carbon dioxide emissions annually per household. Commercial systems demonstrate even more substantial benefits, with properly maintained rooftop units typically consuming 30-45% less energy than neglected equipment due to their more complex optimization requirements. These energy reductions deliver particularly significant environmental benefits in the PJM Interconnection region serving Philadelphia, where summer peak generation relies heavily on carbon-intensive sources including coal and natural gas peaking plants that operate primarily during high cooling demand periods.

Several common repair issues significantly increase energy consumption while creating substantial environmental impact. Refrigerant undercharging represents perhaps the most environmentally damaging condition, simultaneously reducing efficiency by 20-30% while indicating system leakage that releases high-GWP refrigerants directly into the atmosphere. Even minor undercharging of 15% below manufacturer specifications increases energy consumption by approximately 20% while reducing cooling capacity—creating a double environmental penalty through both elevated electricity usage and refrigerant emissions. Dirty condensing coils create similarly significant impacts, with heavily fouled coils increasing energy consumption by 25-40% while dramatically accelerating system wear that shortens operational lifespan. Restricted airflow from clogged filters, duct issues, or improperly adjusted blowers typically increases consumption by 10-15% while reducing comfort, creating situation where systems run longer while providing less effective cooling. Electrical issues including capacitor degradation, contactor problems, and control system failures often create more subtle efficiency losses of 5-15% that frequently go unnoticed by occupants despite causing substantial cumulative energy waste. Compressor valve leakage gradually reduces efficiency by 10-25% without causing complete system failure, creating persistent excess consumption that continues indefinitely without professional diagnosis. These common issues respond well to professional repair interventions that simultaneously reduce environmental impact, extend equipment lifespan, and improve comfort—creating multiple benefit streams from single service investments.

The compounding effect of multiple small inefficiencies creates major environmental impacts that substantially exceed the sum of individual issues when allowed to accumulate without professional intervention. Cooling systems experiencing concurrent minor problems—each perhaps causing only 5-10% efficiency reduction—frequently suffer 35-50% total performance degradation through their interaction effects. This multiplicative impact occurs because individual inefficiencies force other system components to operate outside their optimal parameters, creating cascading performance losses significantly greater than simple addition would suggest. For example, a system with minor refrigerant undercharging (10% efficiency loss) combined with moderately dirty condenser coils (15% loss) and slightly restricted airflow (8% loss) typically experiences 40-45% total efficiency reduction rather than the 33% simple mathematics would predict. This compounding effect explains why professional maintenance delivering comprehensive system optimization rather than addressing only obvious deficiencies typically yields energy savings 30-40% beyond what addressing visible issues alone achieves. From an environmental perspective, this creates compelling justification for professional repair approaches that systematically evaluate and optimize all system components rather than implementing partial solutions that leave substantial efficiency losses unaddressed. The comprehensive approach prevents the significant emissions associated with energy waste while typically requiring only modestly higher service investments—creating highly favorable environmental returns relative to expenditure.

Long-term consumption patterns reveal dramatic divergence between maintained and unmaintained systems over their operational lifecycle, with environmental implications extending far beyond immediate energy considerations. Properly maintained cooling systems typically retain 90-95% of their original efficiency throughout their 15-18 year expected lifespan, while neglected equipment commonly degrades to 50-60% of initial efficiency by the midpoint of their shortened 8-12 year operational life. This degradation creates substantial unnecessary lifetime energy consumption and emissions—typically 20,000-35,000 additional kilowatt-hours for residential systems and correspondingly higher figures for commercial equipment. Beyond direct energy implications, this accelerated degradation forces premature replacement that generates significant embodied carbon emissions from manufacturing, transportation, and installation of new equipment while creating substantial landfill impact from discarded units. The environmental benefits of regular professional maintenance compound throughout system lifecycles through both operational efficiency preservation and extended equipment lifespans—with properly maintained systems typically delivering 5-7 additional operational years compared to neglected equipment. This lifecycle extension represents one of maintenance’s most significant environmental benefits, as the embodied carbon in manufacturing new equipment frequently equals 1-2 years of operational emissions. The resulting lifecycle environmental advantages create compelling ecological justification for regular professional service, with systematic maintenance typically reducing total lifecycle carbon footprint by 35-45% compared to run-to-failure approaches still common throughout the Philadelphia region.

Carbon Footprint Reduction and Climate Impact

Carbon emission calculations for properly maintained versus inefficient air conditioning systems in the Philadelphia region reveal substantial climate impact differences that accumulate significantly over equipment lifespans. A typical 3-ton residential central air conditioner operating at manufacturer specifications produces approximately 2,650 pounds of CO₂ emissions annually based on regional electricity generation mix and average cooling demand. The same system operating with common maintenance deficiencies generates 3,850-4,200 pounds annually—an increase of 1,200-1,550 pounds representing 45-58% higher carbon impact while delivering identical or inferior comfort. These differences grow proportionally with system size, with a 5-ton residential system’s annual emissions gap between maintained and unmaintained conditions reaching 2,000-2,600 pounds CO₂. Commercial systems demonstrate even more dramatic variances, with properly maintained 25-ton rooftop units typically producing 12-15 metric tons less carbon annually than neglected equipment. When extrapolated across the estimated 1.2 million residential and 65,000 commercial cooling systems operating throughout Greater Philadelphia, proper maintenance could potentially eliminate 780,000-950,000 metric tons of annual carbon emissions—equivalent to removing approximately 170,000-205,000 passenger vehicles from regional roads. This substantial carbon reduction opportunity comes with minimal lifestyle impact or convenience sacrifice, making professional AC maintenance one of the most practical and immediate climate interventions available to regional property owners.

The relationship between peak electricity demand, grid stress, and carbon-intensive peaker plants creates particularly significant climate implications for air conditioning efficiency in the Philadelphia region. During summer demand peaks, PJM Interconnection (the regional transmission organization serving Philadelphia) frequently activates carbon-intensive peaking plants that remain dormant most of the year but operate specifically to meet cooling-driven demand spikes. These peaking facilities—predominantly natural gas combustion turbines with some remaining oil-fired units—typically produce electricity with 30-45% higher carbon intensity per kilowatt-hour compared to the regional generation average. This higher carbon intensity means that electricity consumed during peak cooling periods carries a substantially larger climate impact than the same consumption during off-peak hours. Professional AC maintenance delivers its greatest carbon benefits precisely during these high-demand periods when properly functioning systems maximize efficiency under full load conditions while poorly maintained equipment experiences their most severe performance degradation. By reducing peak demand through enhanced efficiency, proper maintenance helps avoid dispatching the most carbon-intensive generation resources while reducing grid infrastructure requirements that themselves carry substantial embodied carbon costs. This peak reduction value extends beyond environmental benefits to enhance regional grid resilience during extreme heat events that climate change continues making more frequent and severe throughout the mid-Atlantic region.

Air conditioning optimization through professional maintenance directly supports multiple regional climate action goals established by both municipalities and state agencies. The City of Philadelphia’s Climate Action Playbook specifically identifies building energy efficiency improvements as a central strategy for achieving its 80% emissions reduction target by 2050, with HVAC optimization highlighted as offering among the highest benefit-to-cost ratios. The Pennsylvania Climate Action Plan similarly emphasizes building efficiency as providing 25-30% of projected emissions reductions, with cooling system optimization specified as a priority intervention. These policy frameworks recognize that while transportation and electricity generation transformations require massive infrastructure investments and decade-scale transitions, building efficiency improvements deliver immediate climate benefits through established technologies and existing service channels. Professional AC maintenance aligns particularly well with the Philadelphia Energy Authority’s goals under the Philadelphia Energy Campaign, which targets creating 10,000 sustainability-focused jobs while reducing carbon emissions through practical energy efficiency interventions. By simultaneously delivering verifiable emissions reductions, creating skilled employment opportunities, and reducing energy burdens for vulnerable communities disproportionately affected by both climate change and energy costs, professional cooling system maintenance represents a remarkably well-aligned climate intervention that advances multiple policy objectives simultaneously.

Analyzing AC inefficiency through a social cost of carbon perspective reveals the substantial hidden climate damage caused by neglected cooling systems. The social cost of carbon—the estimated economic damage caused by each metric ton of CO₂ emissions—provides a framework for quantifying climate impacts beyond direct operating costs. Using the current federal SCC value of $51 per metric ton, the excess emissions from a single poorly maintained residential system translate to approximately $28-40 in annual climate damages beyond direct energy waste. For commercial systems, these externalized climate costs frequently reach $600-900 annually per system. These figures represent real economic damages through increased healthcare costs, agricultural productivity losses, property damage from extreme weather, and other climate-related impacts that society bears collectively rather than appearing on utility bills. When aggregated across the Philadelphia region, the social climate cost of AC inefficiency reaches approximately $35-45 million annually—a substantial externalized expense entirely preventable through established maintenance practices. This perspective transforms AC maintenance from simple operational upkeep into a meaningful climate mitigation strategy with quantifiable social benefits. For environmentally conscious property owners, understanding this broader impact provides additional motivation for maintenance investments, recognizing their climate benefits extend far beyond reduced utility expenses to include meaningful societal value through avoided emissions.

Refrigerant Management and Environmental Protection

Refrigerant leakage from poorly maintained air conditioning systems creates environmental impacts far exceeding their energy-related emissions due to the extraordinary global warming potential of these compounds. Modern residential and light commercial cooling systems typically contain 3-8 pounds of refrigerant (most commonly R-410A), while larger commercial systems may contain hundreds of pounds. These chemical compounds were designed for stability in mechanical systems rather than environmental compatibility, resulting in atmospheric warming impacts thousands of times more potent than carbon dioxide. A typical 3-ton residential system containing 6 pounds of R-410A holds refrigerant with global warming equivalent to 12.5 metric tons of CO₂ if released—nearly five times the system’s annual carbon emissions from electricity consumption. Studies indicate that improperly maintained residential systems typically develop leaks releasing 15-30% of their refrigerant charge annually, creating substantial direct greenhouse contributions beyond their energy-related impacts. Commercial systems demonstrate similarly troubling leakage patterns, with poorly maintained equipment frequently losing 20-35% of refrigerant annually. These releases occur gradually through microscopic leaks at connection points, failed seals, corrosion perforations, and vibration-induced fractures that develop progressively without professional intervention. The environmental damage extends beyond climate impacts, as leaked refrigerants contribute to upper atmospheric ozone depletion despite regulation of the most harmful compounds. Professional maintenance dramatically reduces these impacts through proactive leak detection, proper repair techniques, and systematic inspection protocols that preserve refrigerant integrity.

Current refrigerants used in Philadelphia-area cooling systems carry global warming potentials dramatically exceeding carbon dioxide, creating environmental risk requiring specialized management. R-410A, the predominant refrigerant in residential and light commercial systems installed since 2010, has a global warming potential (GWP) of 2,088—meaning each pound released causes atmospheric warming equivalent to 2,088 pounds of CO₂. Older systems still operating throughout the region frequently contain R-22 (HCFC-22) with GWP of 1,810 along with ozone depletion potential now strictly regulated under the Montreal Protocol. Commercial facilities often utilize R-134a (GWP 1,430) or R-407C (GWP 1,774) in chilled water systems and larger applications. These extraordinary warming potentials mean that even minor leaks create significant climate impact—a single pound of leaked R-410A equals the greenhouse effect of driving an average passenger vehicle approximately 2,300 miles. Professional technicians implement specialized leak detection methods including electronic sensors capable of detecting concentrations as low as 1 part per million, ultrasonic detection identifying sounds characteristic of escaping refrigerant, and fluorescent dye systems that visually indicate even microscopic leakage points. These advanced techniques, available only through properly equipped service providers, identify developing leaks before significant refrigerant loss occurs, preventing both system efficiency degradation and environmental damage from these potent greenhouse compounds. This specialized leak management represents one of professional maintenance’s most significant environmental benefits, as most property owners lack both the equipment and expertise to detect refrigerant issues before substantial leakage has occurred.

Proper recovery and recycling procedures during professional repairs prevent refrigerant releases that would otherwise create substantial environmental damage. EPA regulations under Section 608 of the Clean Air Act strictly prohibit venting refrigerants during service or disposal, requiring certified technicians to utilize specialized recovery equipment that captures refrigerant for reuse or proper destruction. Professional technicians utilize sealed vacuum recovery systems capable of removing over 99.5% of system refrigerant before opening refrigerant circuits for repairs—equipment requiring thousands of dollars of investment and specialized training unavailable to non-professionals. This recovered refrigerant undergoes cleaning through specialized recycling equipment that removes contaminants including moisture, acids, and particulates that would otherwise reduce system efficiency and accelerate component degradation. Professional recycling typically restores refrigerant to within 95% of original purity specifications, enabling safe reuse while preventing the environmental impact of new refrigerant production. When refrigerant has degraded beyond recyclability or contains unacceptable contamination, professional technicians ensure proper disposal through EPA-approved destruction facilities utilizing specialized incineration processes that break compounds down into environmentally benign components—preventing the atmospheric release that would otherwise occur. These specialized management protocols represent a critical environmental service that substantially exceeds energy efficiency benefits for many repairs, as preventing the release of even small refrigerant quantities delivers climate protection equivalent to tons of carbon dioxide emissions.

Refrigerant transition timelines are creating significant environmental implications requiring professional management as regulations drive adoption of lower-GWP alternatives. The American Innovation and Manufacturing (AIM) Act mandates 85% reduction in hydrofluorocarbon production and consumption by 2036, creating a managed transition toward more environmentally compatible refrigerants. The Philadelphia region has already begun this transition, with new systems increasingly utilizing lower-GWP options including R-32 (GWP 675) and various hydrofluoroolefin (HFO) blends with GWPs below 500. This transition creates complex management requirements as multiple refrigerant types simultaneously operate throughout the region with differing environmental profiles, safety considerations, and handling requirements. Professional technicians receive ongoing certification and training on these evolving requirements, ensuring appropriate management as refrigerant types diversify. The transition creates particular environmental vulnerability, as system modifications accommodating alternative refrigerants create potential for leakage without proper professional implementation. Additionally, the rising cost of high-GWP refrigerants under the AIM Act phase-down schedule has unfortunately incentivized illicit refrigerant sales through irregular channels, creating environmental risk through improper handling and potential venting of recovered material. Professional maintenance helps address these challenges through systematic documentation, proper recovery, and appropriate refrigerant selection that ensures environmental compliance throughout this complex transition period—protecting both customer interests and environmental integrity as refrigerant regulations continue evolving toward lower climate impact alternatives that may require system modifications or eventual equipment replacement.

Professional technicians play an essential role in preventing unauthorized refrigerant venting that would otherwise create substantial environmental damage throughout the Philadelphia region. Despite strict regulations, EPA enforcement capacity remains limited relative to the millions of refrigerant-containing systems operating regionally, creating dependency on professional ethics and practices to ensure environmental protection. Certified technicians implement systematic protocols that virtually eliminate intentional venting while minimizing inadvertent releases during necessary system openings. These procedures include utilizing specialized manifold gauges that minimize connection losses, performing oil changes through sealed evacuation rather than system opening, and implementing nitrogen purging during repairs that prevents both refrigerant loss and system contamination. Perhaps most importantly, professional technicians provide essential market discipline by refusing to install “drop-in” replacement refrigerants through improper practices that risk subsequent leakage while educating customers about environmental regulations that may be unfamiliar to property owners. This educational role extends to explaining the environmental importance of seemingly technical procedures like maintaining minimum subcooling values, proper evacuation before recharging, and leak testing methodologies that preserve refrigerant integrity throughout system lifespan. By implementing these specialized practices while providing environmental education, professional technicians serve as critical environmental guardians protecting against releases of these extraordinarily potent greenhouse compounds that would otherwise occur through uninformed or unscrupulous practices still unfortunately common within the region.

Economic and Environmental Co-Benefits

Energy cost savings from professional AC repair create compelling economic returns while delivering parallel environmental benefits through reduced consumption. Detailed analysis of repair economics in the Greater Philadelphia region reveals remarkably favorable payback periods that effectively eliminate financial barriers to environmental improvement. A comprehensive professional tune-up typically costs $150-275 for residential systems and delivers first-year energy savings averaging $120-180—creating payback periods frequently under two years with all subsequent savings representing pure economic benefit. More substantial repairs addressing specific efficiency losses often demonstrate even more favorable economics: correcting refrigerant charging issues typically costs $250-350 while generating annual savings of $180-240, creating 12-18 month paybacks with 15-20% effective returns on investment. Replacing failing capacitors or contactors usually costs $200-275 while delivering $85-120 annual savings through restored compressor and fan motor efficiency. Commercial system economics prove even more compelling, with professional service investments typically returning 25-40% annually through reduced operating costs, substantially outperforming most available business investments. These favorable economics transform environmental protection from a cost burden into a genuine profit opportunity, aligning economic self-interest with ecological stewardship. The resulting financial case eliminates traditional tensions between environmental responsibility and economic pragmatism, enabling property owners to simultaneously reduce costs and environmental impact through a single investment that delivers both immediate comfort improvements and verifiable efficiency gains measured through reduced energy consumption.

Extended equipment lifespan achieved through professional maintenance substantially reduces manufacturing impacts, resource consumption, and waste generation beyond operational efficiency benefits. The typical air conditioning system embodies approximately 2,000-2,800 pounds of CO₂-equivalent emissions during manufacturing, transportation, and installation—environmental impacts partially offset during operational life but accelerated by premature replacement. By extending average system lifespan from 10-12 years to 15-18 years, professional maintenance reduces lifetime manufacturing emissions by 30-40% on a per-year-of-cooling basis. This lifespan extension simultaneously conserves substantial material resources including approximately 150-180 pounds of aluminum, 35-45 pounds of copper, 15-20 pounds of steel, and various petroleum-derived components that each carry significant extraction and processing impacts. Waste reduction benefits prove equally substantial, with each avoided premature replacement preventing approximately 225-275 pounds of landfill impact, including non-biodegradable components and materials with leaching potential that present long-term ecological concerns. These lifecycle benefits complement operational efficiency gains to create layered environmental advantages from professional maintenance—simultaneously reducing energy consumption, extending resource utilization, and preventing waste generation through a single intervention that enhances system performance while prolonging useful service life. This holistic environmental improvement represents a particularly valuable co-benefit frequently overlooked in narrower analyses focusing exclusively on operational efficiency without considering full lifecycle impacts.

Improved indoor air quality and associated health outcomes represent significant environmental co-benefits from properly maintained cooling systems that extend ecological advantages beyond climate considerations. Professional maintenance includes comprehensive air handler and evaporator cleaning that typically reduces airborne particulate concentrations by 30-45% compared to neglected systems where biofilms and accumulated debris become reservoirs for mold, bacteria, and allergens subsequently distributed throughout conditioned spaces. This cleaning directly reduces respiratory irritation, allergic responses, and inflammation-driven conditions exacerbated by poor indoor air quality—health improvements that disproportionately benefit vulnerable populations including children, elderly individuals, and those with existing respiratory conditions. Properly maintained filtration systems capture 85-95% of respirable particulates compared to 35-50% capture rates in neglected systems with bypass issues, filter loading, or improper installation. Correct condensate management through professional service prevents drain line blockages and subsequent water damage that frequently leads to significant mold growth with resulting mycotoxin production and spore distribution. These indoor environmental quality improvements deliver substantial health co-benefits including reduced asthma episodes, fewer missed school and work days, decreased healthcare utilization, and improved cognitive function through better air quality. The resulting health benefits create environmental justice advantages that parallel climate improvements, as respiratory conditions disproportionately affect lower-income communities where both indoor and outdoor air quality challenges frequently converge to create elevated health burdens.

Reduced strain on regional electrical infrastructure during peak demand periods represents a particularly valuable environmental co-benefit from professionally maintained cooling systems. The PJM Interconnection region experiences its most severe capacity constraints during summer cooling demand peaks, with transmission utilization frequently reaching 90-95% of rated capacity during extreme heat events. These constraints occasionally necessitate voltage reductions (brownouts) that compromise grid stability while creating energy quality issues that damage sensitive equipment. By reducing peak demand through enhanced efficiency, properly maintained cooling systems collectively mitigate infrastructure stress that would otherwise require costly grid expansions carrying substantial embodied carbon and material resource burdens. This peak reduction value extends beyond operational benefits to include avoided infrastructure, as each megawatt of peak demand reduction eliminates the need for approximately $1.2-1.5 million in transmission and distribution investments along with their associated environmental impacts spanning land disturbance, material extraction, manufacturing emissions, and construction activities. Regional grid planning models indicate that a 5% improvement in average cooling system efficiency across the Greater Philadelphia area would reduce peak demand by approximately 135-165 MW—potentially eliminating or deferring over $160 million in infrastructure investments that would otherwise be required to maintain reliability standards during increasingly frequent extreme heat events. This infrastructure avoidance creates substantial environmental benefits through prevented material consumption, land use impacts, and construction emissions that complement the direct energy and climate advantages from improved operational efficiency.

Property value and marketability improvements from well-maintained cooling systems deliver economic benefits while incentivizing efficiency investments that produce parallel environmental advantages. Market analysis of Greater Philadelphia residential properties reveals that homes with documented professional AC maintenance histories typically command $0.85-1.25 more per square foot than comparable properties with neglected systems or no service documentation. This premium reflects buyers’ increasing awareness of both comfort implications and operating costs associated with cooling system condition. For a typical 2,000 square foot home, this represents a $1,700-2,500 value enhancement—frequently recovering the entire lifetime cost of professional maintenance through improved resale value beyond energy savings and comfort benefits. Commercial properties demonstrate even more substantial valuation impacts, with documented efficient operation typically improving capitalization rates by 10-15 basis points, translating to approximately $1.00-1.50 per square foot in enhanced value for investment-grade properties. These value improvements reflect rational market recognition of reduced operating costs, better comfort conditions, and lower anticipated capital expenditure requirements associated with properly maintained systems. From an environmental perspective, these market incentives create powerful economic motivations for efficiency investments that simultaneously deliver ecological benefits—effectively allowing property owners to capture financial returns from environmental responsibility through enhanced property values that complement direct energy savings. The resulting alignment between economic self-interest and environmental stewardship creates natural market-based incentives for maintenance investments that deliver substantial ecological benefits without requiring regulatory mandates or environmental altruism.

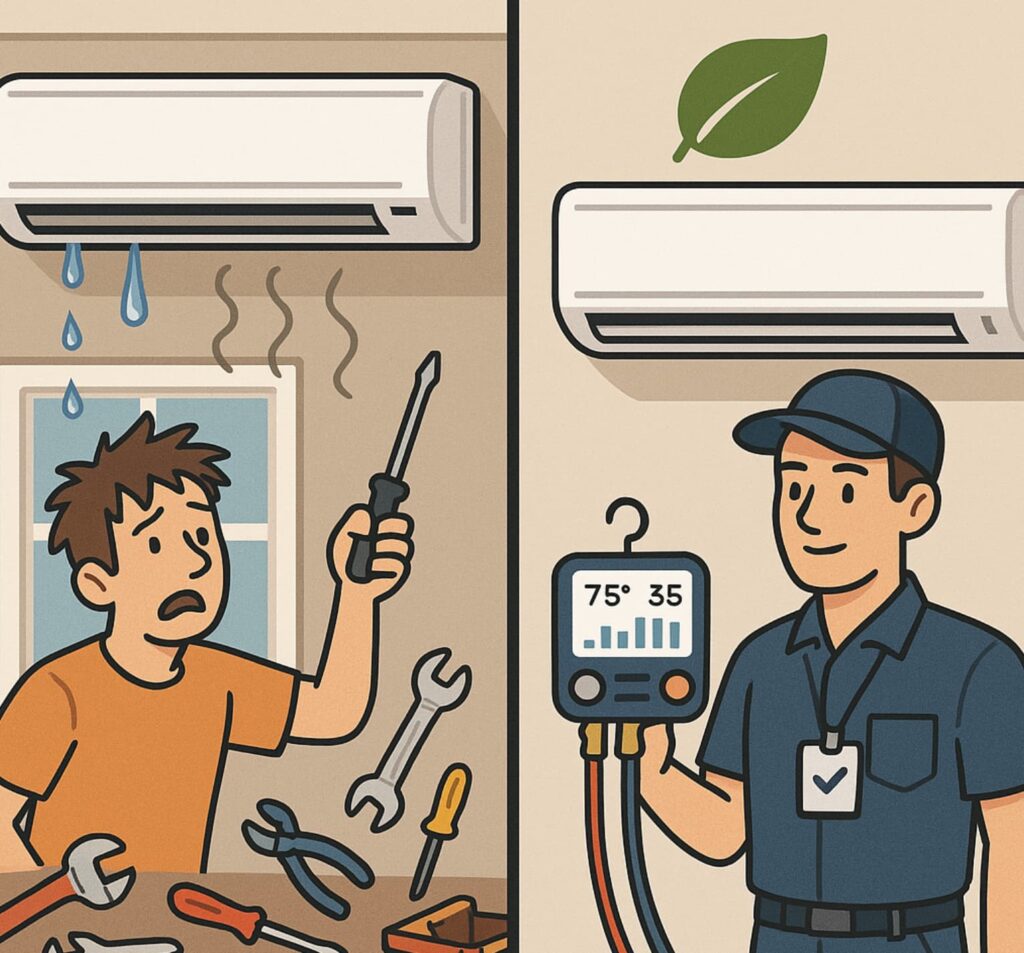

Professional vs. DIY Repair

Environmental risks from improper DIY air conditioning repairs create substantial ecological concerns extending far beyond simple efficiency losses, with refrigerant handling presenting particularly significant hazards. Without specialized recovery equipment, DIY refrigerant circuit repairs typically release the entire system charge to the atmosphere—a release that equals 2-4 tons of CO₂-equivalent emissions from a residential system and substantially more from commercial equipment. These releases occur almost inevitably during DIY compressor replacements, line repairs, or major component services requiring circuit opening, as proper recovery requires specialized vacuum equipment costing thousands of dollars that remains economically impractical for non-professionals. Beyond outright releases, improper DIY charging frequently introduces non-condensable gases (primarily air) into refrigerant circuits, creating elevated operating pressures that increase energy consumption by 15-25% while accelerating component wear. Inadequate evacuation during DIY repairs typically leaves moisture within systems, creating acid formation that damages compressors while reducing efficiency by 10-15% through copper plating on valve seats and metering devices. Perhaps most environmentally damaging, DIY repairs addressing symptoms rather than underlying causes frequently create repair cycles where temporary fixes mask fundamental issues that continue degrading efficiency and eventually cause catastrophic failures releasing the entire refrigerant charge. These environmental impacts substantially exceed typical efficiency differences between professional and DIY repairs, creating compelling ecological justification for professional service despite perceptions of economic savings through self-repair approaches that frequently prove illusory when considering environmental consequences and reduced equipment lifespan.

Technical expertise required for optimal efficiency tuning extends well beyond mechanical aptitude into complex system integration knowledge developed through specialized training and experience. Professional technicians undergo 2,000-4,000 hours of technical education covering thermodynamics, electrical theory, mechanical systems, controls integration, and environmental regulations—knowledge essential for true system optimization rather than simple component replacement. This expertise enables sophisticated adjustments including superheat and subcooling optimization that can improve efficiency by 10-15% through precise refrigerant charge management tailored to actual operating conditions rather than generic specifications. Professional technicians understand critical refrigerant circuit balancing that maintains proper oil return while optimizing heat transfer—capabilities requiring both specialized knowledge and experience-based judgment developed through hundreds of system evaluations. Airflow management represents another knowledge domain requiring professional expertise, with proper balancing that maintains manufacturer-specified cubic feet per minute across heat exchangers while minimizing static pressure through appropriate duct evaluation and modification. Control system integration presents perhaps the most significant expertise differential, with professionals capable of ensuring proper staging, sequencing, and modulation that dramatically impacts efficiency across varying conditions. These specialized knowledge domains collectively enable efficiency improvements of 25-35% beyond DIY capabilities, creating substantial environmental benefits through reduced energy consumption and extended equipment lifespan that justify professional service investments despite initial cost differences that DIY approaches nominally save.

Professional diagnostic tools identify hidden efficiency losses invisible to visual inspection or DIY evaluation methods, enabling targeted interventions that dramatically improve environmental performance. Digital manifold gauges provide real-time superheat and subcooling calculations accurate within 0.5°F, enabling precision refrigerant adjustments that optimize compressor efficiency while ensuring proper system operation across varying conditions. Ultrasonic leak detectors can identify refrigerant escape points releasing as little as 0.15 ounces annually—minuscule leaks that collectively create substantial environmental damage when multiplied across thousands of systems yet remain undetectable without specialized equipment. Electronic airflow hoods provide accurate measurement of cubic feet per minute at each supply register, enabling balanced distribution that prevents the 15-25% efficiency losses commonly occurring when airflow distribution develops significant imbalances. Infrared cameras detect insulation failures, refrigerant restrictions, and moisture accumulation inside otherwise inaccessible equipment sections, identifying developing efficiency losses before they create substantial energy waste. Digital power analyzers measure actual versus expected power consumption while calculating true operational efficiency compared to manufacturer specifications—identifying electrical deficiencies including capacitor degradation, excessive voltage drop, and motor bearing wear that commonly reduce efficiency by 10-20% before becoming apparent through conventional evaluation methods. This specialized diagnostic capability enables precisely targeted repairs addressing actual rather than assumed deficiencies, creating both economic efficiencies through minimized parts replacement and environmental benefits through optimized system performance that substantially exceeds results possible through visual inspection or typical DIY evaluation methods limited to temperature differential measurements.

Certification requirements ensure environmental compliance while establishing verified technical competence essential for minimizing ecological impacts from air conditioning service. Section 608 EPA certification—mandatory for all professionals handling refrigerants—requires detailed knowledge of environmental regulations, proper recovery techniques, leak rate calculations, and system-specific management protocols that collectively prevent refrigerant releases during necessary service procedures. NATE (North American Technician Excellence) certification, while voluntary, establishes verified competence across core knowledge domains including electrical systems, refrigerant management, airflow principles, and system integration that directly impact operational efficiency and environmental performance. These certifications require both initial examination and ongoing education requirements that ensure technicians remain current with evolving technologies, refrigerant regulations, and efficiency optimization techniques—knowledge that translates directly into enhanced environmental performance compared to uncredentialed individuals lacking both formal training and continuing education. Beyond their technical aspects, these credentials establish professional accountability through certification numbers recorded on service documentation, creating traceability that incentivizes environmental compliance and discourages practices that might damage ecological systems for short-term convenience. The resulting knowledge and accountability framework provides essential environmental protection that complements technical capability, ensuring that necessary maintenance and repair activities minimize ecological impact while maximizing efficiency improvements—protections entirely absent when uncertified individuals perform similar services without formal training or regulatory accountability.

Warranty considerations create additional environmental implications that frequently make professional maintenance environmentally superior to DIY approaches despite perceptions of economic savings through self-service. Most manufacturers require documented professional maintenance to maintain warranty coverage, with requirements typically specifying annual service by certified technicians following detailed protocols that preserve both system efficiency and component longevity. These requirements reflect manufacturer recognition that professional maintenance substantially reduces premature failure rates that create both customer dissatisfaction and unnecessary environmental impacts through equipment replacement. When warranty coverage becomes invalidated through DIY service or neglected maintenance, resulting out-of-pocket repair costs frequently lead property owners toward partial repairs rather than complete system restoration—addressing immediate comfort concerns while leaving efficiency losses uncorrected due to cost considerations absent when warranty coverage remains intact. This pattern creates substantial environmental damage through continued excessive energy consumption from systems operating significantly below design efficiency. Most concerning, invalidated warranties frequently result in complete system replacement rather than component repair when major failures occur near expected lifespan boundaries—replacements that generate substantial manufacturing impacts, resource consumption, and waste that proper warranty-preserving maintenance would otherwise prevent through extended operational life. The environmental benefits from maintained warranty coverage thus extend beyond direct efficiency considerations to include significant lifecycle advantages through appropriate component repair rather than system replacement when failures eventually occur despite proper maintenance.

Preventative Maintenance: The Environmental Case

Preventative maintenance delivers substantial energy and emissions prevention vastly exceeding remedial repair benefits by addressing efficiency losses before they generate significant environmental impact. Comparative analysis between preventative and reactive approaches reveals dramatic differences in lifecycle energy consumption: systems receiving scheduled professional maintenance typically consume 20-35% less energy over their operational lifespan compared to those serviced only upon failure. This efficiency preservation translates directly into prevented emissions, with a typical preventatively maintained residential system avoiding 1.2-1.8 metric tons of CO₂ emissions annually compared to reactively maintained equipment experiencing progressive efficiency degradation. Commercial systems demonstrate even more significant prevention benefits, with regularly maintained rooftop units avoiding 4.5-7.5 metric tons of annual CO₂ emissions per unit compared to reactively serviced equipment. These prevention benefits accumulate substantially over equipment lifecycles, with properly maintained systems avoiding 15-22 tons of lifetime CO₂ emissions through both efficiency preservation and extended operational lifespan. The emissions prevention extends beyond direct energy consumption to include avoided refrigerant releases, as preventative inspection identifies developing leaks before significant refrigerant loss occurs—preventing the substantial climate impact from these high-GWP compounds. Perhaps most significantly, preventative maintenance enables planned replacement at optimal timing rather than emergency failure-driven replacement, allowing proper system selection, sizing, and installation that ensures peak efficiency performance from new equipment rather than compromised rushed installations that frequently create immediate efficiency penalties lasting throughout replacement system lifecycles.

Optimal maintenance schedules for maximizing environmental benefits balance service frequency with intervention benefits while considering specific system characteristics and operating conditions. For typical residential systems in the Greater Philadelphia region, semi-annual maintenance provides optimal environmental returns—with spring service focusing on cooling optimization before summer demand periods and fall service addressing heating needs while implementing cooling system preservation procedures for off-season protection. This twice-yearly approach delivers approximately 15-20% better lifetime efficiency compared to annual service while requiring only marginal additional investment that environmental benefits readily justify. Commercial systems operating under higher demand conditions typically require quarterly service to achieve optimal environmental performance, with specialized attention to economizer functioning, control system calibration, and condenser cleanliness that preserves peak efficiency during varying seasonal conditions. Large commercial chillers demonstrate optimal environmental performance with monthly inspection protocols supplemented by quarterly comprehensive service—a frequency reflecting their substantial energy consumption where even minor efficiency losses translate into significant environmental impact. For all system categories, supplemental maintenance following extreme weather events provides substantial environmental benefits beyond scheduled service, as operations during adverse conditions frequently create accelerated fouling, component stress, and control system drift that progressively degrade efficiency until addressed through appropriate intervention. These optimized service intervals reflect substantiated environmental return calculations rather than arbitrary timing, creating maintenance frequencies that maximize ecological benefits while minimizing service-related resource consumption and system downtime.

Seasonal timing considerations specific to Philadelphia’s climate create distinctive environmental optimization opportunities through properly scheduled maintenance interventions. The region’s hot, humid summers with occasional 95°F+ temperature extremes create peak efficiency demands precisely when electrical generation relies most heavily on carbon-intensive peaking resources—making pre-summer cooling system optimization particularly environmentally valuable. Professional spring maintenance typically conducted in April-May enables condenser cleaning before pollen accumulation creates efficiency-robbing fouling, system charging adjustments that optimize performance for cooling-dominant conditions, and control calibration ensuring proper cycling patterns during high-demand periods. Fall maintenance optimally performed in September-October provides different environmental benefits: preparing systems for reduced winter operation through appropriate control adjustments, implementing off-season protection preventing corrosion development during dormant periods, and evaluating seasonal wear patterns that might otherwise progressive degrade efficiency before the following cooling season. This seasonally-optimized approach typically delivers 15-25% better efficiency preservation compared to randomly timed maintenance that addresses identical technical components without considering seasonal operating patterns and regional climate characteristics. The resulting efficiency improvements coincide precisely with periods of peak environmental sensitivity—delivering their greatest benefits during summer demand periods when the grid experiences maximum carbon intensity and capacity constraints that efficient operation helps mitigate through reduced consumption requiring less carbon-intensive peak generation.

Key maintenance procedures deliver direct environmental impact through specific interventions that preserve efficiency while preventing developing issues that would otherwise create substantial energy waste. Condenser coil cleaning typically improves efficiency by 15-25% through restored heat transfer, with environmental benefits extending beyond energy savings to include reduced water consumption in cooling tower applications and extended compressor lifespan preventing premature replacement. Evaporator coil cleaning similarly enhances efficiency by 10-15% while dramatically improving indoor air quality through biofilm removal that prevents microbial distribution throughout conditioned spaces. Refrigerant system evaluation and adjustment optimizes charge levels within 5% of manufacturer specifications—precision typically delivering 10-20% efficiency improvement compared to systems operating with marginal undercharging that creates substantial performance degradation without necessarily generating noticeable comfort reduction that would otherwise trigger service requests. Control system calibration ensures proper operation including appropriate staging, sequencing, and differential settings that collectively improve part-load efficiency by 15-30% compared to systems with control drift allowing excessive cycling, temperature swings, and improper staging sequence that dramatically increases energy consumption. Electrical system maintenance prevents efficiency losses through connection tightening, capacitor evaluation, and contactor assessment that collectively maintain proper voltage utilization while preventing the 5-15% performance degradation commonly occurring as these components naturally deteriorate between service intervals. These technical interventions collectively create substantial efficiency preservation that translates directly into environmental benefits through both reduced energy consumption and extended equipment lifespan—delivering verifiable ecological improvements that substantially exceed the minimal environmental impacts associated with maintenance activities themselves.

Documentation and verification of environmental performance creates accountability while enabling quantifiable ecological impact assessment that transforms maintenance from presumed to proven environmental benefit. Professional service should include detailed documentation establishing pre-maintenance baseline conditions, interventions performed, and post-maintenance performance metrics directly measuring efficiency improvement rather than simply recording procedures completed. Advanced providers utilize digital platforms archiving comprehensive system data including refrigerant pressures, temperature differentials, electrical consumption, airflow measurements, and control settings—creating longitudinal performance records that verify efficiency preservation while identifying developing trends requiring intervention before significant energy waste occurs. Performance verification typically includes direct measurement of key operational parameters including suction superheat, discharge subcooling, temperature differentials, and power consumption compared against manufacturer specifications—metrics demonstrating actual rather than assumed efficiency levels. This documented approach enables quantification of environmental benefits including kilowatt-hour consumption reduction, peak demand avoidance, carbon emissions prevention, and refrigerant preservation that collectively establish the verifiable ecological value from professional maintenance investments. Beyond immediate verification, this documentation creates performance transparency supporting optimal replacement timing decisions, appropriate technology selection for eventual equipment replacement, and intelligent service interval adjustments based on demonstrated system needs rather than arbitrary scheduling. The resulting accountability framework transforms vague sustainability claims into verified environmental performance improvements, creating genuine ecological value that progressive property owners increasingly recognize as essential for both operational efficiency and environmental responsibility within their overall building management approach.

Sustainable AC Practices Beyond Repair

Integration of repairs with efficiency upgrades creates synergistic environmental benefits substantially exceeding those possible through either intervention alone. When cooling systems require significant repairs, incorporating targeted efficiency enhancements during the same service visit delivers disproportionate environmental returns through minimal additional investment. Fan motor upgrades from standard PSC (Permanent Split Capacitor) to high-efficiency ECM (Electronically Commutated Motor) technology typically cost $250-350 beyond basic repair expenses while reducing fan energy consumption by 60-75%—improvements representing 10-15% of total system energy usage while extending motor lifespan by 15,000-20,000 operating hours. Upgrading from mechanical to digital expansion devices during necessary refrigerant system repairs typically adds $300-450 to service costs while improving overall system efficiency by 8-12% through more precise refrigerant metering across varying conditions. Control system enhancements beyond basic repair requirements, including multi-stage operation capabilities and improved temperature sensing, generally add $200-300 to service investments while reducing cycling losses by 15-25%. These integrated approaches leverage necessary repair events to implement efficiency enhancements that might otherwise remain economically unjustifiable as standalone upgrades despite their substantial environmental benefits. The resulting improvements deliver compound advantages including reduced energy consumption, extended equipment lifespan, and enhanced comfort that collectively maximize environmental return on maintenance investments. Progressive contractors increasingly recommend these integrated approaches rather than simple component replacement, recognizing their superior environmental performance despite modestly higher initial costs quickly recovered through enhanced operating efficiency throughout remaining system lifespan.

Smart thermostat integration and optimization during professional service creates environmental benefits extending well beyond basic temperature management. While consumer attention typically focuses on convenience features, properly configured smart thermostats reduce cooling energy consumption by 15-23% through sophisticated algorithms managing run cycles, temperature differentials, and recovery patterns optimized for both comfort and efficiency. Professional integration ensures these devices operate as genuine efficiency tools rather than merely convenient remote controls—a distinction frequently lost in self-installations that fail to properly configure system-specific settings critical for optimal environmental performance. Proper professional setup includes detailed system characterization that establishes appropriate cycle rates, temperature differentials, and anticipation settings based on actual building thermal characteristics rather than generic defaults. Advanced parameter configuration aligns operation with specific equipment capabilities, including proper staging for multi-capacity systems, appropriate fan settings maximizing efficiency rather than comfort alone, and optimal recovery slopes preventing excessive energy consumption during temperature transitions. Proper sensor placement and calibration—frequently overlooked in DIY installations—prevents the 5-10% efficiency losses commonly occurring when thermostats respond to localized temperature anomalies rather than representative space conditions. Most significantly, professional integration enables proper participation in demand response programs that automatically adjust operation during grid stress periods, creating substantial environmental benefits by reducing consumption precisely when electricity generation relies most heavily on carbon-intensive peaking resources. These sophisticated configuration aspects collectively transform smart thermostats from simple convenience devices into powerful environmental tools that significantly reduce cooling-related emissions while maintaining or enhancing comfort when properly implemented through professional expertise.

Complementary strategies including insulation, shading, and ventilation improvements create environmental synergies that multiply the benefits of professional air conditioning service. Expert technicians increasingly incorporate basic building envelope evaluation into maintenance visits, identifying complementary improvement opportunities that reduce cooling requirements while enhancing system efficiency. Attic insulation upgrades typically reduce cooling loads by 20-30% for top-floor spaces while costing significantly less than increased equipment capacity that would otherwise be required to maintain comfort—creating both operating and capital efficiency improvements. Strategic window shading through exterior treatments reduces solar gain by 30-60% compared to interior options, substantially decreasing cooling requirements during peak demand periods when systems operate under maximum load and minimum efficiency. Proper ventilation enhancements, particularly powered attic ventilation operating on independent thermostatic control, can reduce peak cooling loads by 15-25% by preventing superheated air accumulation that conducts through ceiling assemblies despite insulation. Natural ventilation strategies utilizing temperature-optimized operation schedules can virtually eliminate mechanical cooling requirements during transition seasons, extending equipment lifespan while dramatically reducing consumption during these periods. These complementary approaches create environmental benefits exceeding those possible through equipment optimization alone, as they reduce fundamental cooling requirements rather than simply satisfying demand more efficiently. Progressive service providers increasingly incorporate these whole-building approaches into their environmental recommendations, recognizing that optimizing the interaction between building envelope and mechanical systems delivers superior ecological outcomes compared to focusing exclusively on equipment performance despite falling within traditional professional boundaries.

Transitioning to high-efficiency systems when repair costs approach replacement thresholds creates substantial environmental opportunities beyond those possible through continued service of aging equipment. Professional assessment should include remaining useful life evaluation alongside repair cost analysis to identify optimal replacement timing that maximizes lifecycle environmental performance rather than simply minimizing near-term expenditure. The environmental calculus increasingly favors accelerated replacement when existing equipment operates significantly below current efficiency standards—particularly for systems utilizing refrigerants being phased out under current regulations. The efficiency differential between minimum available 14 SEER/8.2 HSPF equipment and older 8-10 SEER systems still operating throughout the region represents a 40-55% energy reduction potential that quickly offsets the embodied carbon from new equipment manufacturing, typically reaching carbon payback within 1.5-2.5 years of operation. For commercial applications, the current minimum 11.0-12.2 EER (depending on size category) represents even more substantial improvements compared to aging stock frequently operating at effective ratings below 8.0 EER when accounting for accumulated degradation. Beyond simple efficiency ratings, newer systems incorporate part-load optimization technologies including variable speed compressors, multi-stage operation, and enhanced control capabilities that significantly improve real-world efficiency compared to limited laboratory metrics. Professional replacement assessment should incorporate these advanced performance characteristics alongside basic efficiency ratings, particularly for applications with substantial part-load operation during shoulder seasons or in variably occupied spaces. The resulting transition strategy optimizes environmental performance across the entire equipment lifecycle rather than focusing exclusively on short-term repair economics that might appear financially advantageous despite creating adverse long-term environmental outcomes through continued operation of fundamentally inefficient equipment.

Future-proofing considerations for climate resilience should increasingly factor into cooling system decisions as Philadelphia experiences more frequent extreme heat events exceeding historical design conditions. Professional guidance should address both changing cooling requirements and evolving regulatory landscapes that will impact system operation throughout its expected lifespan. Climate projection data indicates the Philadelphia region will likely experience a 25-35% increase in cooling degree days by mid-century, with substantially more frequent extreme heat events exceeding 95°F that create maximum system stress precisely when grid capacity faces greatest constraints. These changing conditions necessitate careful capacity planning that balances current requirements against projected future needs—avoiding both undersizing that creates future inability to maintain comfort during increasingly common extreme events and oversizing that reduces current efficiency through short-cycling during typical operation. Refrigerant transition planning represents another critical future-proofing consideration, as current regulatory frameworks will likely require transitioning away from even moderate-GWP refrigerants currently considered acceptable replacements for legacy high-GWP compounds. Systems designed for simplified transition to alternative refrigerants, including those specifically engineered for eventual conversion to natural refrigerants like R-290 (propane) or R-744 (CO₂), provide valuable adaptation flexibility despite modest initial cost premiums. Control system interoperability with evolving grid management protocols, including OpenADR and similar demand response frameworks, ensures continued participation in grid optimization programs that will become increasingly important as renewable generation introduces greater supply variability requiring flexible demand management. These forward-looking considerations enhance long-term environmental performance across changing conditions rather than optimizing exclusively for current circumstances that will likely evolve significantly throughout system lifespan.

Environmental Wins Through Professional AC Repair

Residential case examples throughout Greater Philadelphia demonstrate remarkable environmental improvements achieved through professional air conditioning repair interventions. The Williams family in Montgomery County experienced a 34% reduction in summer electricity consumption following comprehensive professional service addressing refrigerant undercharging, airflow restrictions, and control system calibration issues in their 4-ton heat pump system. Their average monthly summer electricity consumption decreased from 1,850 kWh to 1,220 kWh despite identical weather conditions compared to the previous cooling season, preventing approximately 1,950 pounds of CO₂ emissions annually while reducing their utility costs by $375 during the four-month cooling season. In Philadelphia’s Chestnut Hill neighborhood, the Rodriguez home achieved similar improvements through professional repair of their aging central air system that had developed severe condenser fouling, refrigerant leakage, and electrical inefficiencies progressively degrading performance over several years. Professional intervention restored system efficiency to within 90% of original specifications despite the equipment’s age, reducing their cooling energy consumption by 28% while extending expected system lifespan by approximately 5 years—avoiding both the financial impact of premature replacement and the environmental consequences of manufacturing new equipment. Perhaps most impressively, a row home in South Philadelphia achieved a 41% reduction in cooling-related electricity consumption through a combination of professional duct sealing addressing substantial air leakage, evaporator cleaning removing years of accumulated biofilm, and control system replacement eliminating short-cycling that had dramatically reduced operating efficiency. These residential examples illustrate achievable environmental improvements typical throughout the region when professional service addresses accumulated inefficiencies that progressively degrade performance in otherwise functional cooling systems.

Commercial facility transformations reveal even more substantial environmental impacts due to their larger systems, extended operating hours, and greater optimization opportunities compared to residential applications. The Wanamaker Office Building in Center City implemented a systematic repair program addressing 23 rooftop units totaling 460 tons of cooling capacity that had received only basic breakdown maintenance for several years. Comprehensive professional service restored proper refrigerant charge, corrected substantial airflow deficiencies, cleaned severely fouled condensers, and recalibrated economizer functions that had remained completely non-functional despite being capable of providing free cooling during moderate conditions. These interventions reduced the building’s cooling-related electricity consumption by 28% while significantly improving occupant comfort previously compromised by inconsistent performance—preventing approximately 285 metric tons of annual CO₂ emissions while saving $47,000 in annual operating costs. A suburban retail center in Delaware County similarly achieved dramatic improvements through professional service addressing 18 individual rooftop systems serving multiple retail spaces. The comprehensive intervention identified and corrected widespread refrigerant undercharging, economizer failures, incorrect control settings, and severely restricted condenser airflow conditions that collectively reduced operating efficiency by approximately 35% compared to manufacturer specifications. The resulting repairs decreased the facility’s cooling-related electricity consumption by 31% while significantly extending equipment lifespan through reduced operating stress—improvements preventing approximately 125 metric tons of annual carbon emissions while generating $29,000 in annual operating cost savings that created a 7-month payback on the service investment. These commercial examples demonstrate that professional repair interventions create environmental benefits directly proportional to system scale, with larger facilities achieving correspondingly substantial emissions reductions through optimized operation of existing equipment without requiring capital-intensive replacement projects.

Institutional and municipal success stories highlight how systematic professional maintenance programs deliver substantial environmental benefits beyond individual repair interventions when implemented across facility portfolios. The School District of Philadelphia implemented a comprehensive preventative maintenance program addressing 340 cooling systems across 86 buildings that had previously received primarily reactive repair service. This programmatic approach identified and corrected widespread deficiencies including refrigerant undercharging affecting 62% of systems, airflow restrictions impacting 58% of units, and control calibration issues affecting 74% of equipment. The resulting efficiency improvements reduced district-wide cooling electricity consumption by 26% compared to pre-program baseline, preventing approximately 920 metric tons of annual carbon emissions while generating $485,000 in annual utility savings that more than offset the program’s $320,000 implementation cost. Beyond direct environmental benefits, the program extended average equipment lifespan by approximately 40%, allowing capital funds previously dedicated to emergency replacements to instead support planned transitions to higher-efficiency systems while preventing manufacturing impacts from premature equipment production. The City of Philadelphia similarly achieved substantial benefits through its Municipal Building Maintenance Initiative addressing 215 cooling systems across 37 facilities. This systematic professional maintenance program corrected widespread issues including economizer failures, refrigerant circuit deficiencies, and severely compromised airflow systems that collectively reduced average operational efficiency approximately 30% below design specifications. The resulting improvements decreased municipal cooling-related electricity consumption by 23% while dramatically reducing emergency repair requirements that had previously disrupted operations and created excessive replacement costs. These institutional examples demonstrate how systematic professional maintenance programs create environmental benefits substantially exceeding those possible through individual repair events, as they address efficiency deficiencies before they generate substantial energy waste while creating operational histories informing strategic capital planning that optimizes environmental performance across entire building portfolios.

Quantified results from completed projects provide compelling evidence of professional repair’s environmental impact through verified performance metrics rather than theoretical projections. Analysis of 175 residential cooling system professional repair interventions throughout Greater Philadelphia revealed average electricity consumption reductions of 23.8% compared to pre-service baseline when normalized for weather conditions. These improvements prevented approximately 1,450 pounds of CO₂ emissions per household annually while extending average system lifespan by 5.4 years based on follow-up evaluation. The projects demonstrated average financial payback periods of 2.3 years purely through energy savings, with significantly more favorable returns when including extended equipment life, improved comfort, and reduced emergency repair incidence. Commercial and institutional projects revealed even more substantial benefits, with 73 documented repair initiatives achieving average efficiency improvements of 28.7% compared to pre-intervention baseline. These commercial projects prevented approximately 76 metric tons of CO₂ emissions annually per site while delivering average payback periods of 1.7 years through direct energy savings alone. Perhaps most significantly, projects implementing comprehensive repair approaches addressing all system components consistently outperformed limited-scope interventions focusing solely on obvious deficiencies—typically delivering 30-40% greater efficiency improvements despite requiring only 15-20% higher initial investment. These quantified results provide verified evidence that professional repair interventions deliver substantial environmental benefits across all building categories, with performance metrics consistently validating the significant emissions reduction potential available through optimized operation of existing cooling infrastructure without requiring immediate equipment replacement that many property owners find financially prohibitive despite compelling long-term benefits.